III bolsters Taiwan Bicycle and Related Component Industry Chain to Develop the “Production Decision Support System with Digital Twins Solution for Bicycle Industry (PDSS)”, winning the 2020 R&D100 Awards

Date: 2020/10/05

Caption: Supported by the science and technology special project of the Department of Industrial Technology (DoIT) of the Ministry of Economic Affairs, 6 initiatives from Taiwan were recognized by this year's R&D100 Awards. The Ministry of Economic Affairs held the "2020 R&D100 Awards Press Conference" on October 5th . The picture shows that the Vice Minister of the Ministry of Economic Affairs Chuan-Neng Lin (Middle), Deputy Director General of the Bureau of Energy, the Ministry of Economic Affairs Chun-li Lee (the 4th from the right), Assistant Director-general of the Department of Industrial Technology (DoIT), the Ministry of Economic Affairs Chung Guo Yang (the 4th from the left), Director General of the Institute for Information Industry C.H. Cho (the 5th from the right), President of the Industrial Technology Research Institute Edwin Liu ( the 6th from the left), President of Formosa Plastic Group Jason Lin (the 6th from the right), CEO of the Metal Industries Research and Development Center Chiu-Feng Lin (the 5th from the left), Director General of the Regional Industry Service Division, the Institute for Information Industry Garfield Hung (the 2nd from the left) and all venerable representatives from the legal persons as well as companies of the industry took a picture together.

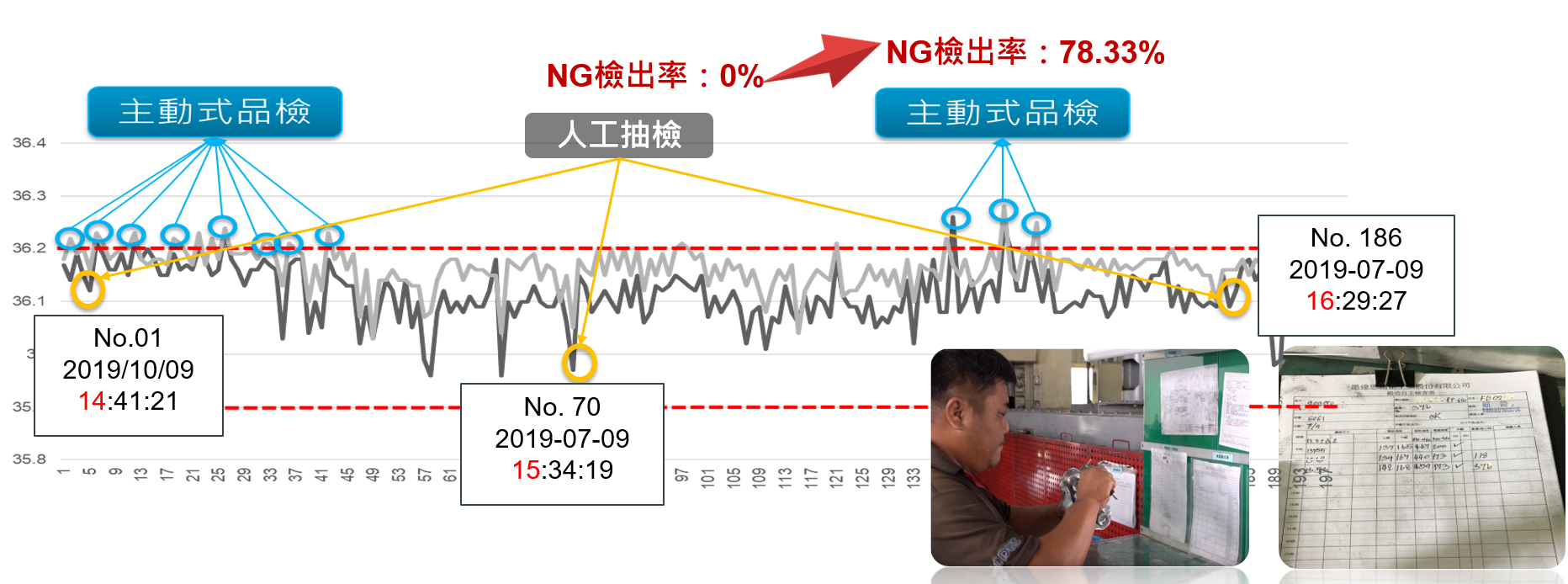

Caption: III developed the “Production Decision Support System with Digital Twins Solution for Bicycle Industry (PDSS)”, which won this year's R&D100 Awards. The picture shows the comparison between the proactive quality inspection twin module and the traditional quality inspection mode. (The yellow circles are manual inspections at regular intervals, and none of them have any defects; the blue circles are the workpieces predicted by the module to be defective, and the NG detection rate is as high as 78.33%.)

Caption: III developed the “Production Decision Support System with Digital Twins Solution for Bicycle Industry (PDSS)”, which won this year's R&D100 Awards. The picture shows the comparison between the proactive quality inspection twin module and the traditional quality inspection mode. (The yellow circles are manual inspections at regular intervals, and none of them have any defects; the blue circles are the workpieces predicted by the module to be defective, and the NG detection rate is as high as 78.33%.)

Known as the Oscar of the science and technology industry, the R&D100 Awards announced its 58th winners recently. This year, supported by the science and technology special project of the Department of Industrial Technology (DoIT) of the Ministry of Economic Affairs, the Institute for Information Industry (III), with the technology of “Production Decision Support System with Digital Twins Solution for Bicycle Industry (PDSS)”, stood out from more than 1,000 innovative technologies from countries all around the world and won this year's US R&D 100 Award. The Ministry of Economic Affairs is schedule to hold the "2020 R&D100 Awards Press Conference" on October 5th .

Backed by PDSS, Taiwan Bicycle and Related Component Industry Muscles for Global Markets.

The bicycle industry of Taiwan has a complete industrial chain and company settlements. Among these companies, Giant and Merida are two of the world-renowned bicycle brands. In Taiwan, there are more than 800 registered companies related to the industry of bicycles and related components, including enterprises that make key components such as frames, chains, and brakes, etc. However, facing the trend of global transformation, the bicycle and related component industry of Taiwan which carries its own unique features is currently facing problems from information, equipment, and manufacturing aspects.

III Regional Industry Service Division (RISD) Director Shon Wang pointed out that in terms of the information aspect of Taiwan’s current bicycle and related component industry chain, data could not be properly collected due to insufficient digitization. Additionally, because various machines have different processing methods and the specifications of various custom-made machines (special purpose machines) are not the same, the information format of the production parameters gathered is not unified; with regards to the perspective of equipment, while more than 90% of Taiwanese companies are small and medium-sized enterprises, in comparison to large enterprises, they are lagging behind in automation upgrading in the face of the current situation of M-shaped industry; in terms of manufacturing process, in response to market customization, small quantities and short delivery times, companies need to change production lines frequently. Furthermore, since adjusting manufacturing process parameters relies mostly on operating experience, quality stability could easily be affected, which could lead to a large number of defective products.

To this end, III Regional Industry Service Division (RISD) uses the " Production Decision Support System with Digital Twins Solution for Bicycle Industry (PDSS)" technology to create the quality cause analysis and prediction system specifically for the Taiwan bicycle and related component industry. This system replaces passive manual inspections with proactive production quality causal analysis methods and uses digital twin prediction models to greatly reduce the costs and time of system introduction and to significantly improve production efficiency and reduce defect rates. Through heterogeneous source networking and synchronous processing technology, this system collects various data in the factory such as the mold pressure, non-contact multi-point mold temperature, data of materials and parts, effective working condition vibration, and workpiece measurement size to build a history for detected features. This team has also developed intelligent analysis services such as proactive prediction as well as cause diagnosis. By active prediction and improvement, this system can reduce the probability of post-refining processing, and create a intelligent manufacturing solution with high precision and low repair rates.

III Regional Industry Service Division (RISD) Director General Garfield Hung pointed out that the intelligent transformation of Taiwan's bicycle and related component industry can successfully help break through the traditional SMEs' problem, which is the lack of capital to undergo the process of intelligent transformation and to quickly respond to the ever-changing global market so that these firms can improve production quality, reduce costs, and quickly adjust production lines to enter the international market. <